In modern

industry, the centrifugal compressor increases the gas pressure as a key fluid

machinery. The diffuser plays a crucial role among the many components of a

centrifugal compressor. In particular, with its unique design and high

efficiency, the pipe diffuser is essential in centrifugal compressors with high-pressure

ratios.

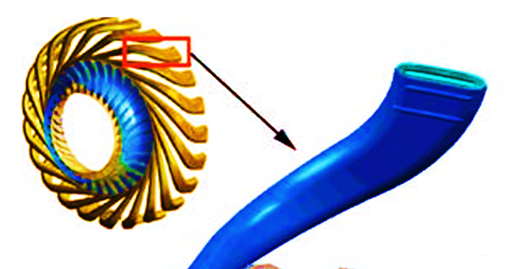

The pipe diffuser is a

unique diffuser designed for use in centrifugal compressors. It guides the

airflow through a series of tubular structures, converting the kinetic energy of

the high-speed airflow at the impeller exit into pressure energy. Compared to

traditional vane-less diffusers, the pipe diffuser is more effective in

controlling the flow direction of the airflow, reducing flow losses along the

path, and thereby improving the compressor's operational efficiency.

Figure 1: Schematic Diagram of the Tube

Diffuser

Key Design Points of Pipe Diffusers

- Geometric Parameter Optimization: The design of the pipe diffuser

involves multiple geometric parameters, such as throat diameter, outlet

diameter, and diffuser length. Optimizing these parameters is crucial for

enhancing the diffuser's performance.

- Flow Matching: To ensure the airflow entering

the diffuser has the appropriate flow characteristics, the design of the pipe

diffuser needs to be closely matched with the impeller's exit

characteristics. This helps to minimize flow losses.

- Internal Flow Control: The pipe diffuser can effectively

control the direction and velocity distribution of the airflow through

careful design of the internal structure, reducing flow separation and

vortex formation. This improves the efficiency of pressure conversion in

the gas.

Performance Advantages of the Pipe

Diffuser

- High Efficiency: The pipe diffuser can maintain a

high adiabatic efficiency across a wide range of flow rates due to its

ability to effectively control airflow.

- Wide Flow Range: The pipe diffuser's optimized

design accommodates various operating conditions and offers a broad flow

range.

- Compact Structure: Tube diffusers generally have a

smaller size and weight, making them particularly advantageous in

applications with limited space.

TurboTides in Pipe Diffuser Design

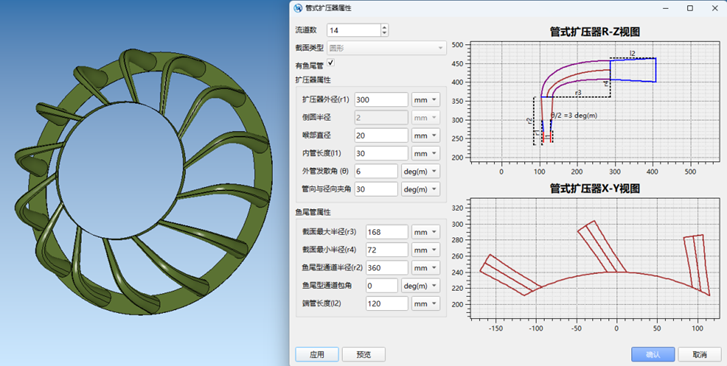

The TurboTides

geometric module supports parametric modeling of pipe diffusers, allowing users

to customize various parameters of the pipe diffuser, including the inner tube

length, diffuser divergence angle, diffuser outer diameter, throat diameter,

and the radial angle, as shown in the figure below.

Figure 2: Parametric Definition of Pipe

Diffuser

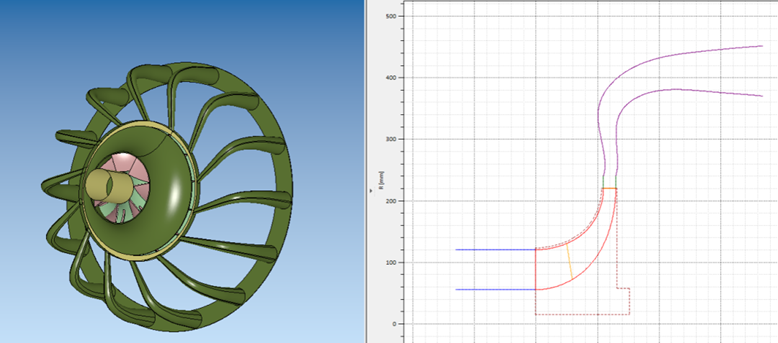

The

parametrically generated tubular diffuser and its flow path information are

shown in the figure below.

Figure 3: Parametric Centrifugal Compressor

with Pipe Diffuser in TurboTides

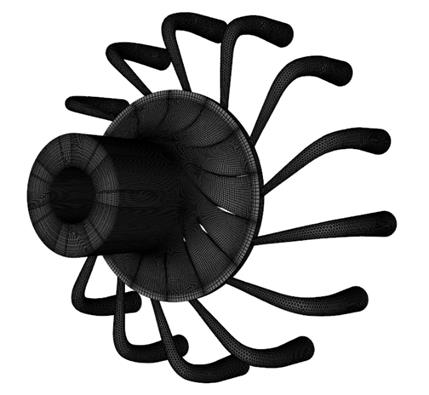

After

completing the parameterization, TurboTides supports switching to the CFD

module to automatically generate meshes with a single click and import boundary

conditions, as shown in the figure below.

Figure 4: Mesh Generation for Compressor with Pipe

Diffuser

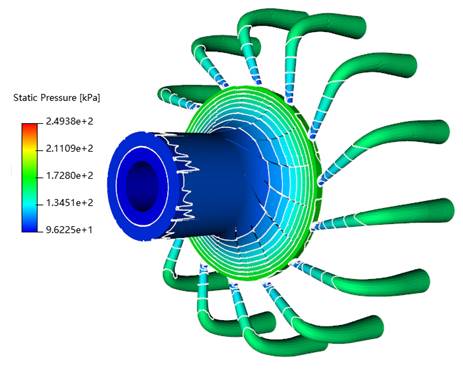

After the mesh

is generated, CFD simulation and analysis can be conveniently performed. The

CFD simulation results for a centrifugal compressor with a pipe diffuser are

shown in the figure below.

Figure 5: CFD Simulation Results for a

Centrifugal Compressor with a Pipe Diffuser in TurboTides

Conclusion

The pipe

diffuser represents a significant innovation in centrifugal compressor design.

By optimizing the process of converting airflow kinetic energy, it can

significantly enhance compressor efficiency and performance. With the

advancement of Computational Fluid Dynamics (CFD) and numerical simulation

technologies, the design and optimization of pipe diffusers will become more

precise, leading to broader applications across various fields.

TurboTides'

support for modeling and analyzing pipe diffusers makes their development more

efficient and streamlined. The parametric modeling functionality allows simple,

flexible, and easily adjustable diffuser designs. Combined with the seamlessly

integrated CFD simulation module, performance simulation becomes more accurate

and convenient.

In the future,

TurboTides will continue to support the development of pipe diffusers, which

will contribute to improved energy utilization efficiency and drive industrial

progress.

Please contact us if you have any questions or would like to schedule a live demonstration.